Image source: https://www.sbmar.com/wp-content/uploads/2015/09/Yellowtail-Engine-install-close-to-finish-11.jpg

Beware of asbestos lagging. Many older vessels and marine engine installations had exhaust methods that have been lagged with asbestos tape and rope. Asbestos sound-proofing was also favourite in older boats.

You will comprehend your engine is hydrauliced if or not it's far going to not flip over - in entire after a long sailing period - and you've got removed the starter motor and ensured it works. To remove water from inside the combustion chambers, first remove all injectors, crank engine over to blow water out, refit injectors, bleed injector lines, and leap. Then depart motor taking walks until eventually exhaust sorted out.

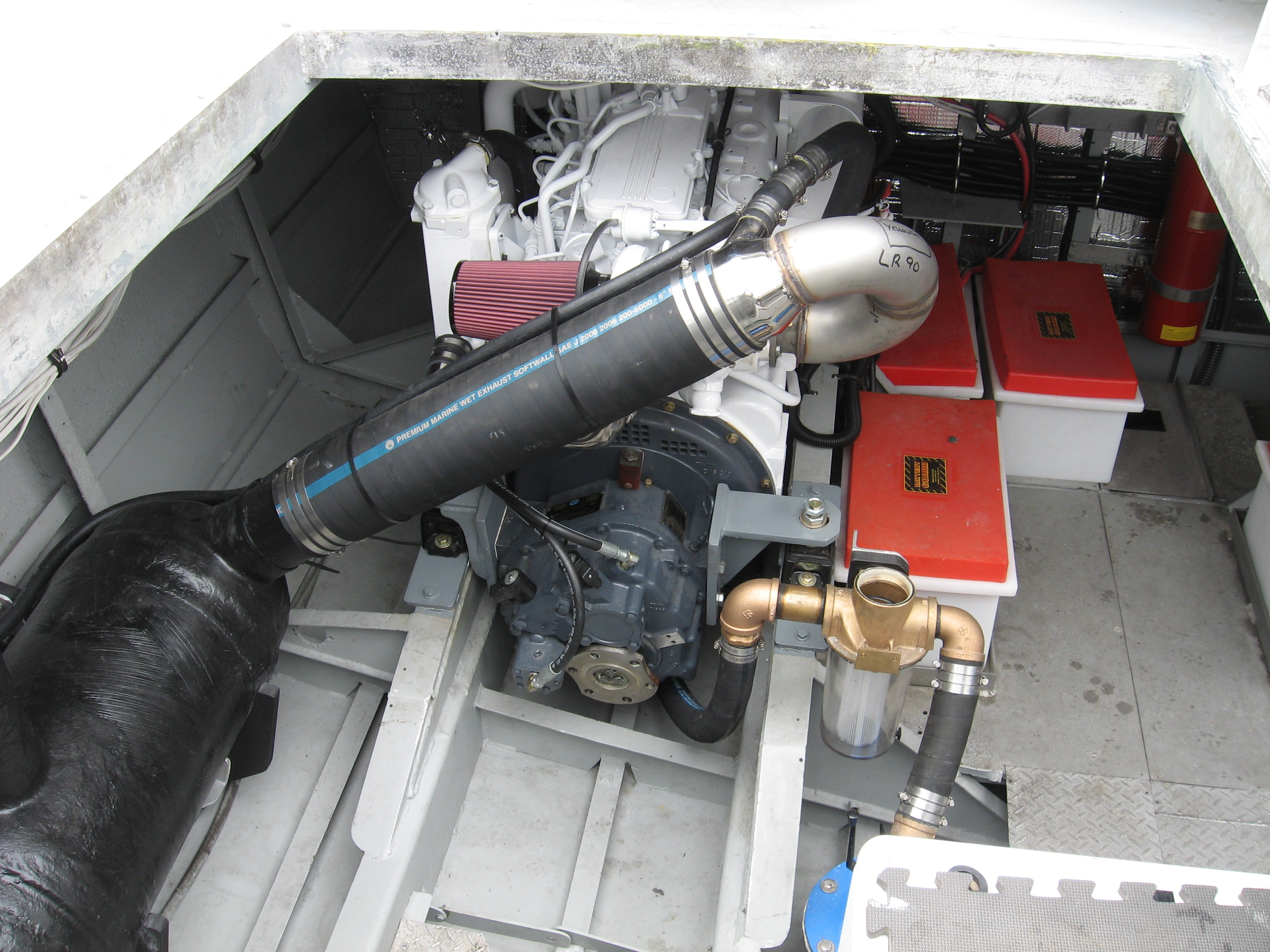

Marine exhausts methods are an oversized and usally not noted a component to a marine engine. Most vessels have a 'moist' exhaust machine. Salt water is injected at the riser - the outlet for exhaust from the exhaust manifold. This mixture of exhaust gas and water is then passed through a series of bends until eventually it exits the boat, preferably at the stern.

Exhaust gas is poisonous and can cause sea sickness and headaches. Replace any defective parts all of a unpredicted. Use double hose clamps on each joint or, preferably, superb clamps, bolt style, and exhaust cement if desire be. Hot sections could be lagged with fiberglass tape to preclude burns.

Check to look that the riser is de facto not coked up or corroded - a favourite situation. To examine the exhaust riser remove the exhaust hose from the riser (usally a troublesome system) and look up the pipe to look if that is constrained by exhaust/salt build up. If build up is excessive the riser will would possibly have to be removed to examine the engine end of the pipe. Coke can also be scraped out to provide a short term fix teenagers usally the riser will would possibly have to be replaced. There are aftermarket methods which differ in quality. Make particular you slot the desirable design for the application.

How Marine Exhaust Systems Work

Ensure your water-lock is low adequate and big adequate to preserve each of the water in exhaust machine. Is there a gooseneck or central vertical loop in the exhaust hose at the transom exit? Is there a siphon ruin and is it functioning properly - no leaking valves?